RO4003C 32mil High Frequency PCB Immersion Gold Applied In Preamplifier

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

RO4003C 32mil High Frequency PCB Immersion Gold Applied In Preamplifier

PCB properties

<table border

RO4003C 32mil High Frequency PCB Immersion Gold Applied In Preamplifier

PCB properties

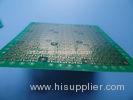

| PCB SIZE | 45 x 51mm=1PCS |

| BOARD TYPE | |

| Number of Layers | Double sided PCB |

| Surface Mount Components | YES |

| Through Hole Components | NO |

| LAYER STACKUP | copper ------- 35um(1oz)+plate TOP layer |

| RO4003C 32mil (0.813mm) | |

| copper ------- 35um(1oz)+plate BOT Layer | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 6.3mil/7.6mil |

| Minmum / Maximum Holes: | 0.66/1.2mm |

| Number of Different Holes: | 5 |

| Number of Drill Holes: | 58 |

| Number of Milled Slots: | 1 |

| Number of Internal Cutouts: | 0 |

| Impedance Control | NO |

| BOARD MATERIAL | |

| Glass Epoxy: | RO4003C 32mil (0.813mm), Tg 288 |

| Final foil external: | 1.5oz |

| Final foil internal: | 0oz |

| Final height of PCB: | 0.9mm ±0.1 |

| PLATING AND COATING | |

| Surface Finish | Electroless Nickle over Immersion Gold (ENIG)( 1 µ" over 100 µ" nickle) |

| Solder Mask Apply To: | Top and Bottom, 12micon Minimum. |

| Solder Mask Color: | Green, PSR-2000GT600D, Taiyo supplied. |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | TOP |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo Supplied. |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | Plated Through Hole(PTH) |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| APPLICATION: | Preamplifier |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Advantages

a) RO4003C substrate. Excellent high frequency performance.

b) Immersion gold finish. High solderability, no stressing of circuit boards and less contamination of PCB surface.

c) No MOQ, low cost for small quantity prototypes and samples.

d) An ideal substrate for broadband applications.

More Applications in Electronics

N Router

USB 3G

USB Adapters

GPS Track

Long Range Wifi

PC and Notebook

Multilayer and High Layer PCB

Automobile

Backplanes

Servers and Networking

PCB knowledge: HASL

Hot air solder leveling is for short HASL, which is a common type of surface finish used on printed circuit boards (PCBs). We dipped the PCBs (with exposed copper surfaces) into a bath of molten solder, then remove the excess solder on PCB surface and in the holes by strong hot air(which we call it HASL machine) to get a glossy layer of coating.

One is alloy of tin and lead. The temperature of smelting furnace for Tin/Led is about 240. Another one is pure tin, because lead is harmful to human body, EU has forbidden using tin/lead. So the popular is pure tin or HASL Lead free. The temperature of smelting furnace for pure tin is highly at 300, and plus the operating environment, high temperature and high etching are great harm on PCB itself. Due to its hot air generated, HASL has low planarity. It makes this surface finish unsuitable for use with fine pitch components. It has hidden danger of board warp or twist under high thermal stress. To avoid this disadvantages, high Tg material and PP are took into consideration for some PCB user. But it also has excellent wetting during component soldering and it can avoid copper corrosion. So it is also mostly used in single sided PCB, Double sided PCB and some multilayer PCB.

Multilayer PCB Stackup: 4 layer .062” Finished Thickness

FAQ

Do you sell via in pad PCB?

Yes. Via in pad (VIP) is a good real estate saving. We offer this kind of PCB for many applications like microcontroller, GPRS etc.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

BICHENG ENTERPRISE LIMITED [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)